Add to Cart

Name:

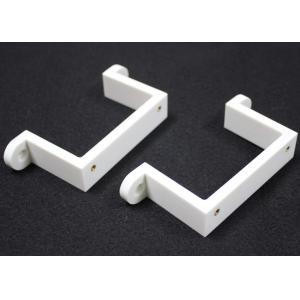

Plastic CNC Prototype Machining For Handle CNC Prototype Service

Detail:

| Plastic materials: | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PBT+GF30%...etc. |

| Other materials: | Rubber, Silicone rubber, LSR, aluminum, zinc...Metal...etc. |

| Quality: | ROSH and SGS standard |

| Feature: | Non marking and Non flash |

| Size: | According to your drawing |

| Color, Quantity, Unit price, Tooling cost, Tooling size: | To be discussed |

| Mold structure: | Injection Mould, Plastic Mold, Overmould, 2k mould, Die-Casting Mould, Thermoset Mold, Stack Mold, Interchangeable Mold, Collapsible Core Mold, Die Sets, Compression Mold, Cold runner system LSR Mold,…etc. |

| Mould Base: | HASCO standard, European standard, World standard |

| Mould Base Material: | LKM, FUTA, HASCO, DME, etc. or as per customer’s requirement. |

| Surface Finish: | Texture (MT standard), high gloss polishing |

| Finish: | Mirror finish etc. |

About Us:

Boyi Prototype - a World Class Prototyping and Prototype Manufacturing company

Rapid prototypes,3D printing(SLA,SLS), Vacuum casting, precision CNC machining, rapid prototyping, aluminium alloy cnc machining parts, plastic injection molding and pressure die casting are some of our main service we offer that support our core business Rapid prototyping, Rapid tooling,molding, surface treatment and mass production. This make Boyi Prototype a world class reliable supplier for your projects.

Benefits:

● We know what the customer need, our aims is achieve customer expectations.

We are confident in our latest technology developments and manufacturing experience.

Our reliable and loyal technical team in our factory have well knowledge in various types of machining and processing control. (We always consider and plan the manufacturing process in advance to make sure products are of good quality.Our Engineer have designed and developed many equipments and fixtures to ensure the processes to be stable and have best results.

● Quality Control

Our team are dedicated in technology development and be careful in process design and definition, you are ensured to get high quality services from us.Full set of services includes inspection check list, dimension measurements, functional and pre-assembly test and analysis, drop test, technical advice feedback, etc. We will do these to make sure the parts leave our factory in good quality.

● Competitive Cost:

Our workshop based in China Mainland, We always explore effective ways in cost control as we know cost is one of the critical factors for business.

We have huge and superior material supply chain to maintain our material support and stability in cost control,

Our strategy is to build up a long term relationship with our customers.Therefore we believe that our cost is absolutely competitive.

Apart from that, we do multiple inspections, which means not only the quality staff doing inspection, production and project engineer will also carry out brief inspections themselves when the parts pass to them. This act further reduces any mistakes and defects in production.

Product Type:

| Product Type | |||

| (1) 3D Printing (Rapid Prototype, SLA, SLS)/ SLA Rapid Prototyping | |||

| (2) Plastic Prototype/ CNC Papid Precision Machining | |||

| (3) Vacuum Casting(silicon moulds) | |||

| (4) Aluminium Alloy CNC machining | |||

| (5) Reaction Injection Molding | |||

| (6) Post Productin Finishing | |||

| (7) Quality Assurance (Q.A.) | |||

| (8) Plastic Injection Mold/ Injection Molding | |||

| (9) Rapid Plastic Injectin Molding | |||

| (10) Rapid Pressure Die Casting | |||